Can a single angle slow down digital tool-data workflows?

Turns out – yes.

At a recent DIN 4000-90 meeting in Dresden, experts from Siemens, Renk, Zoller, Kennametal and others uncovered something surprising: for quite some time, many stakeholders have been using the same parameter with two different meanings.

And nobody really noticed – until this meeting where this gap was impossible to ignore.

For two days, our host xPLM welcomed the DIN group right next to Dresden’s Striezelmarkt. The setting was festive (there was Glühwein), but the discussions around clamping tool holders were very real.

Many of us came expecting heated debates over details. Instead, we found a fundamental misunderstanding between how the standard defines key characteristics and how they are actually used in practice.

DIN 4000 meeting participants at Dresden’s Striezelmarkt – theory, practice and a bit of Glühwein.

When the tool cutting edge angles don’t mean what people think they mean

Back in the meeting room at xPLM, Functional height (A4) wasn’t the only place where theory and practice drifted apart. The tool cutting edge angles E1 and E2 have been understood by users very differently in the standard text and in day-to-day use.

The best example is E1, the tool cutting edge angle.

Inside the DIN 4000-90 session at xPLM: turning abstract definitions into something people can actually work with.

E1: The Angle Everyone Used — But No One Defined the Same Way

In DIN 4000-90, E1 is defined as the angle of the insert relative to the feed direction – effectively, the angle of the insert to the workpiece in cut. On paper, that sounds precise.

In practice, it’s almost impossible to specify reliably in a data exchange: the tool manufacturer doesn’t know the customer’s workpiece or application.

So what did users do?

They redefined it. Quietly, pragmatically – they used E1 as the angle of the insert relative to the toolholder body. Same field name, different reference, but suddenly the value became something they could actually work with in catalogues, CAM or 3D tool libraries.

So who is wrong here?

After the discussions in Dresden, the answer is: both sides have a point.

- The E1 as it was defined doesn’t really help in day-to-day data exchange.

- The E1 as it was actually used is very useful – it just needs a cleaner definition relative to the reference axis.

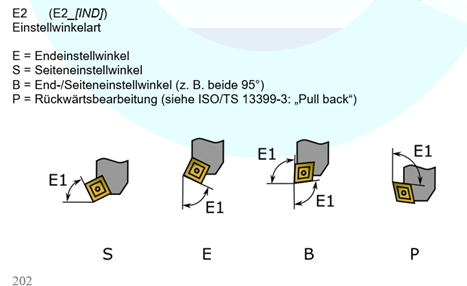

E2 – cutting edge angle type: E = End cutting edge angle, S = Side cutting edge angle, B = Both end/side edge angle (e.g., 95°), P = Pull back (see ISO/TS 13399-3: “Pull back”)

What‘s next?

The Dresden meeting was a first step: it surfaced where definitions and real use cases diverge and confirmed that E1/E2 and A4/A41 in DIN 4000-90 need to be brought back in line with practice, not the other way around.

Next stop: Nuremberg

On 10–11 March 2026, Kennametal will host an ad-hoc meeting on DIN 4000/4003-90 in Nuremberg (Nürnberg). That’s where our technical working group will dive deeper into E1/E2 and A4/A41 and turn the Dresden insights into concrete proposal texts.

Dresden’s Frauenkirche – a reminder that even long-standing structures can be rebuilt on clearer foundations. The same now needs to happen for DIN 4000-90.

Why It Matters

At first glance, this might look like a niche standards topic.

But every time a parameter like E1 or A4 means different things to different systems, three things happen:

- Tool data becomes harder to automate and reuse.

- Integrations between catalogues, CAM and 3D generators become fragile.

- Engineers waste time fixing what a shared definition could have solved.

Standards like DIN 4000 are supposed to unify us. But when theory and practice diverge, they can also divide.

The good news? Now that the misunderstanding is out in the open, there’s a chance to fix it – and make the standard serve the real needs of manufacturers and users.

If you work with DIN 4000 data in catalogs, CAM systems or tool databases:

– How do you use E1 and E2 today?

– Where do current definitions get in your way?

Your feedback helps ensure that the next round of DIN 4000-90 doesn’t become just another misunderstanding between theory and practice.