“Our customers are very successful in using ToolsUnited’s automated data transfer to initially populate master data in SAP for their tool management with Factory Control Center (FCTR).”

YOUR COMPANION FOR INTEGRATIVE PLM

At DSC Software AG, we are passionate about bringing people, processes, and systems together. Our hearts beat for your product data.

Get inspired by our fascination with integration. Committed to innovation, empathy, and partnership, we accompany you in the concrete implementation of your digitalization strategy: with SAP as the central, digital data basis for your business processes, enhanced with tailor-made best-practice solutions.

As a long-term SAP partner, we stand by your side as an experienced and fantastically connected companion. Our team combines more than 1,100 years of PLM know-how directed to one single goal: creating the best possible solution to your individual challenges. We help you convert your brilliant ideas into smart products even more quickly and keep being ready for the future.

Find out more: https://dscsag.com/

Your Companion for Integrative PLM

DSC Software AG is one of the leading consulting and integration experts in the field of SAP PLM. We accompany industrial enterprises in the concrete implementation of digitalization strategies focusing on the product lifecycle in SAP, with our competence in integration, processes and implementation.

Together with SAP, we develop the strategic integration platform for SAP PLM: SAP Engineering Control Center | SAP ECTR – simply “integrative PLM”.

As an SAP Platinum partner, we promote the Digital Transformation with currently about 700 customers. With lots of know-how, and solutions

always tailored to our customer’s needs.

Find out more: https://dscsag.com/

About Factory Control Center | FCTR

Factory Control Center | FCTR complements the SAP-assisted product development process with CAM integration, complete tool data management in SAP, and detailed planning of tools and operating re-sources, connected to shop floor systems.

This allows the seamless organization in SAP even of processes like determining tool requirements, providing NC programs, and documenting correction data for the tool presetters. SAP standard objects such as Document, Material, Bill of Material, Equipment, Routing, and Production Resource are the basis of FCTR, and the solution supports all order-related processes in manufacturing.

One system centrally manages all of the relevant data, and automatically provides this data where necessary.

Find out more: https://www.dscsag.com/de/losungen/produkte/factory-control-center-fctr

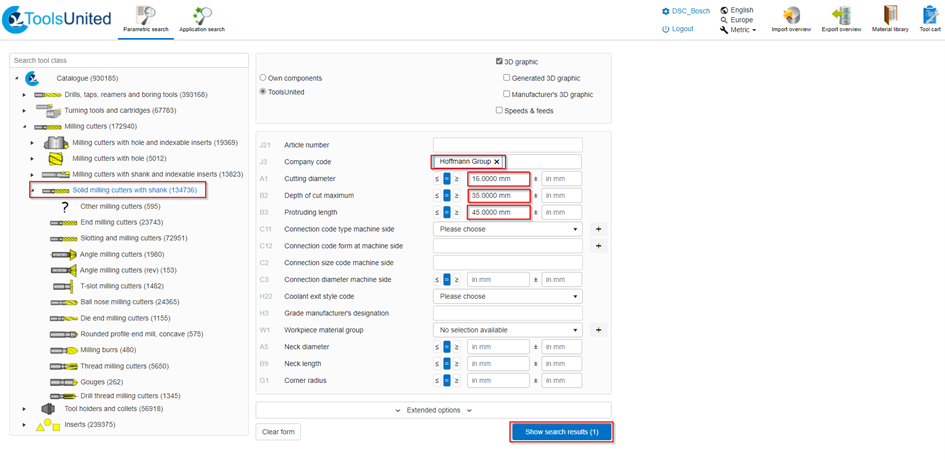

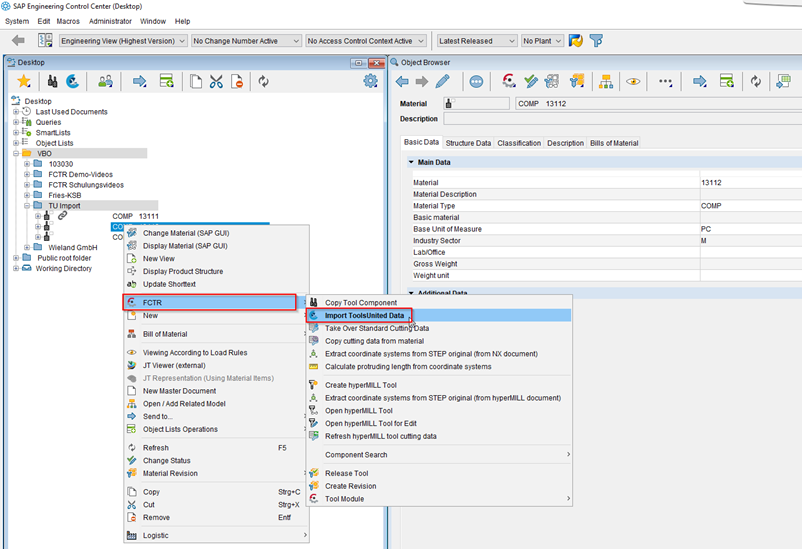

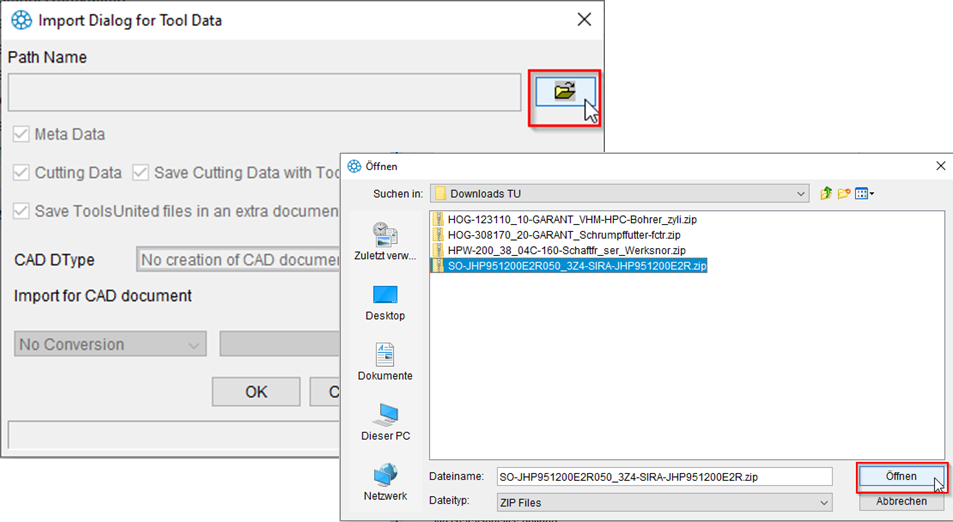

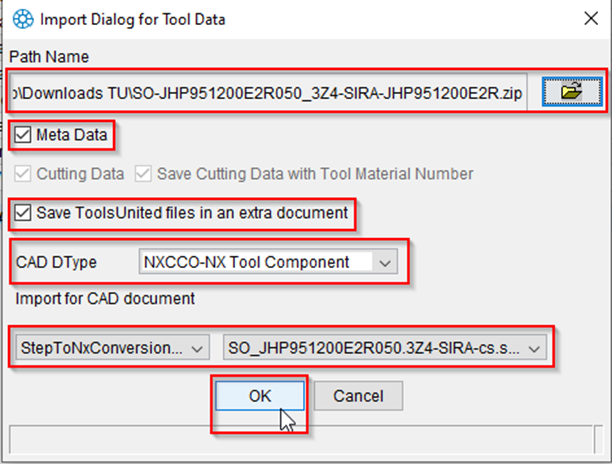

Follow these steps to successfully import tools from ToolsUnited to Factory Control Center | FCTR:

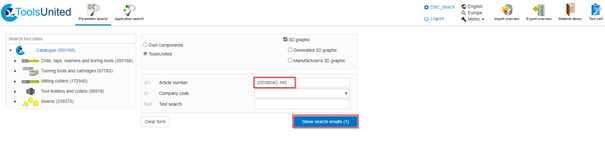

Another option is to directly enter the article number of the tool manufacturer.

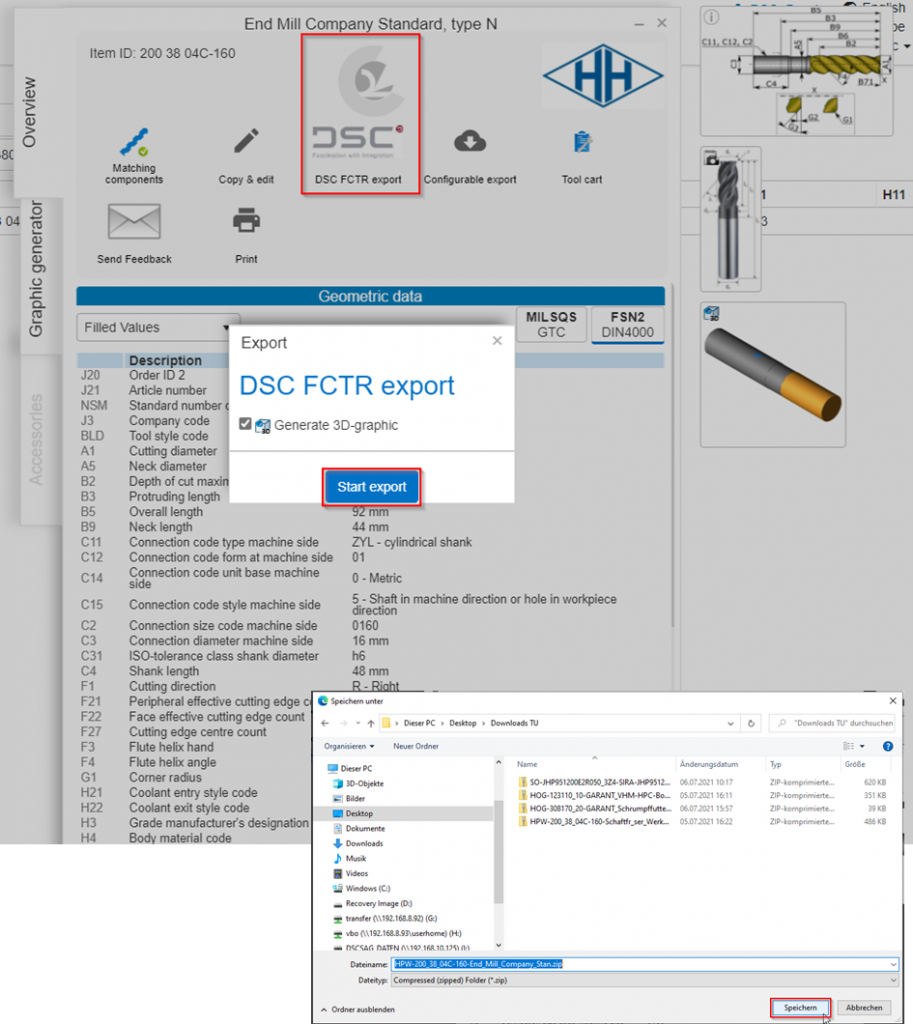

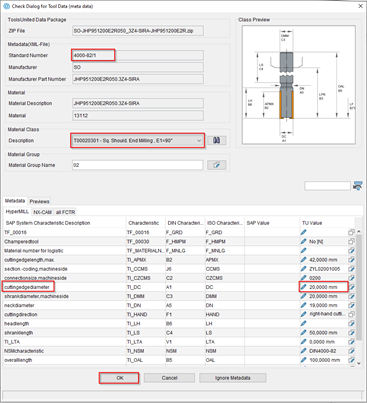

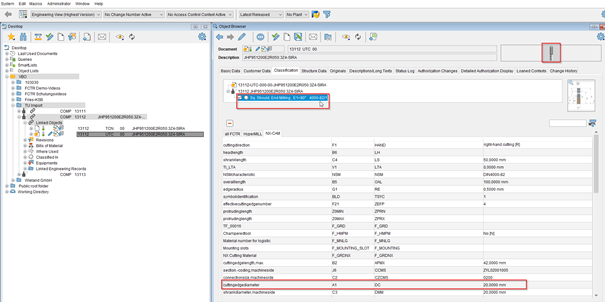

Check the Import Dialog for Tool Data, and confirm with OK if all of the data is correct.

Before the import process starts, the tool data is checked. For example, the “Standard Number”, “Description” and “cuttingedgediameter”.

If the import was successful, the tool can be displayed on the “Classification” tab, and the DIN characteristics, such as the “cuttingedgediameter” can be checked again.

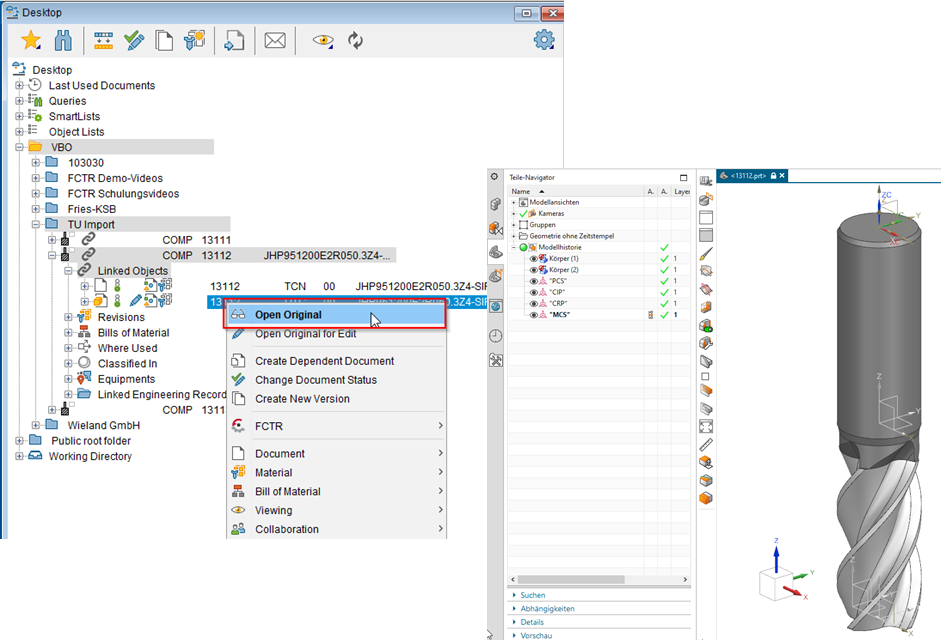

A right mouse click on the UTC object opens the 3D model in the CAD environment.